Ние можем да предоставим услуга за пълно управление на Вашия проект, от дизайн, изчисления, доставката на материали, монтаж, до измерване и валидиране на резултатите.

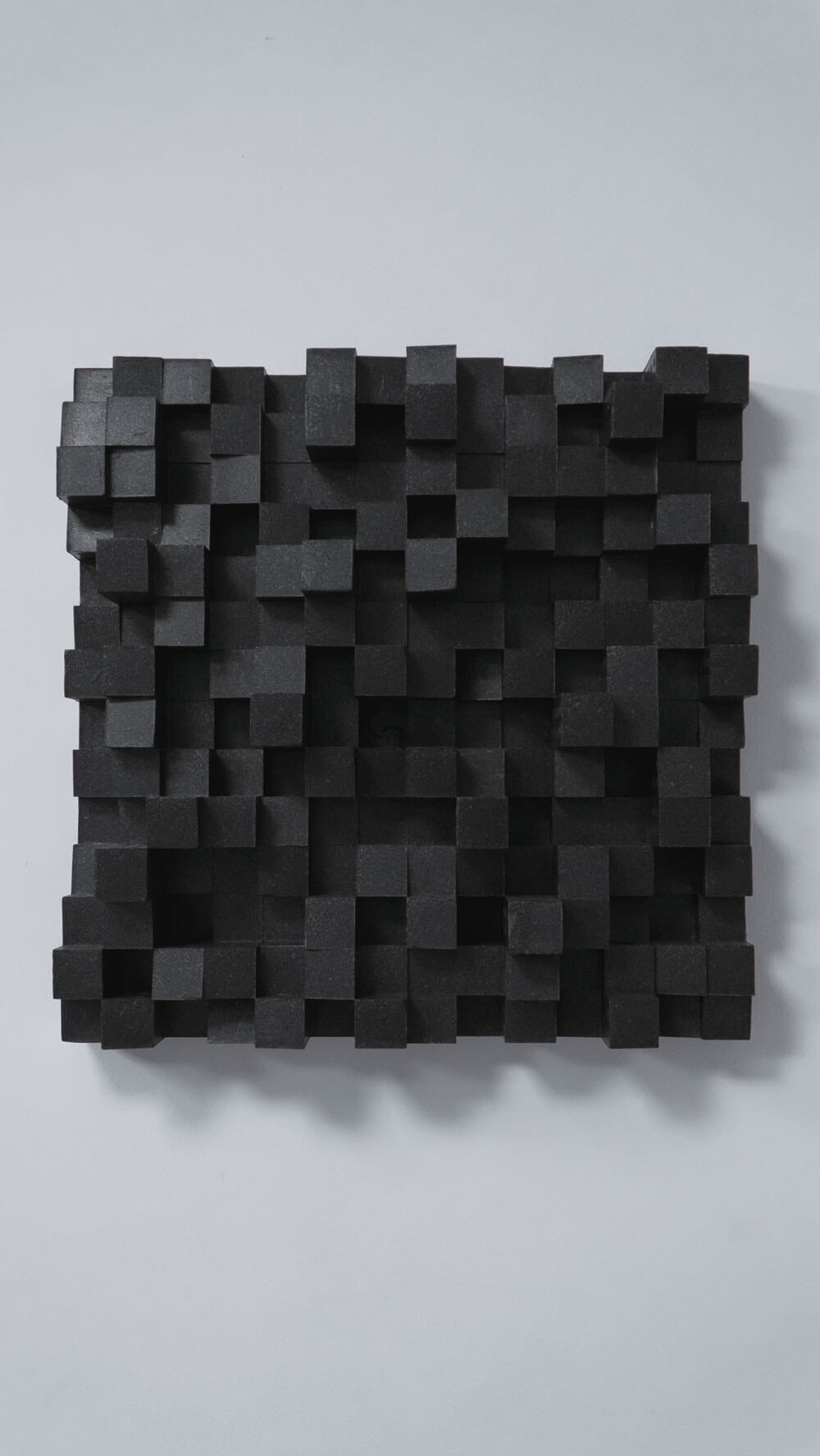

Acoustic Force е екип от специалисти с над 10 години опит в сферата на шумоизолацията и акустиката. Ние консултирахме, проектирахме, изработихме и монтирахме :

Проекти за акустично третиране на музикални студия и подкаст студия – група Молец, Алекс Нушев (APMg stydio), музикаленият продуцент Станислав Велев(Stani) – Evince Music, Йоан Николаев (L Padr3) – Popfolk Academy и NoStress Studio, Владимир Aмпов (Графа), White sound Studio, студиото на известния диригент Стоян Стоянов в Дубай, Ангел Ковачев (Ангел от Ангел и Моисей), The House Studio

множество проекти за шумоизолация на офиси, от които офисът на Soft AG, Проктър енд Гембъл, Adata pro, Мегатрон, Ототон, Qcredo, Ingram Micro, Офис на Банка ДСК, Еконт академия в гр. София и гр. Русе, Trading 212 и още много други;

Обществени сгради като ресторантa на сградата Office X, хотел Grand Hotel Terme Banya, една от малкото евангелистки църкви с акустично третиране ЕПЦ Варна.

Индустриално обезшумяване на Била, завод Симид, завод Гласко и завод Етем.

Над 500 успешно реализирани проекти за шумоизолация на жилища

Във връзка с програмата на Европейския съюз „Адаптирана работна среда“, чиято цел е подпомагане на малки, средни и големи предприятия в прехода към климатично неутрална икономика, нови модели на работа, здравословна и безопасна работна среда, бихме искали да уведомим всички наши клиенти, че типа услуги, които ние от Acoustic Force предлагаме, се включват в регламента […]

В днешно време всички сме заобиколени от дразнещ шум, който влияе на нас и нашите близки. Източниците могат да бъдат различни: строителна дейност, силна музика от партита, обществен транспорт и др. Когато живеете в апартамент или в къща, тези звуци ни пречат да се отпуснем след тежкия работен ден и пълноценно да отпочинем. За щастие, […]

Нека ви запознаем със системата Нивелатор Саунд. Специфично за нея е, че запазва максимално височината на помещението. Системата предлага минимална плътност от 6 см, измерена от най-ниската точка на всяка стена. За извършване на монтажа, първата стъпка е подготовка на стената. Следваща стъпка е разчертаване на конструкцията и определяне поставянето на профилите – по дължина или […]

0883 40 00 61

info@acousticforce.bg

ул. „Русалийски проход“ 1B, 1407, гр. София